Espiral UF

Las membranas espirales de ultrafiltración de Alfa Laval se basan en una construcción única de material de soporte de polipropileno o poliéster en un diseño higiénico de ajuste completo que proporciona condiciones óptimas de limpieza. Las membranas en espiral están disponibles con diferentes tipos de membranas de ultrafiltración y en diferentes combinaciones de longitud, diámetro y tamaño del espaciador de alimentación

The pores of the membranes used for Alfa Laval ultrafiltration spiral membranes are small, having a cut-off range from 1,000 to 100,000 molecular weight (MWCO), and the applied pressure is relatively low. Salts, sugars, organic acids and smaller peptides pass through the pores of the membrane, whereas proteins, fats and polysaccharides are retained.

Using appropriate ultrafiltration membranes also makes it possible to fractionate a feed stream into two distinct streams, with each stream containing dissolved components with different molecular weights.

The Alfa Laval ultrafiltration spiral membranes are a popular choice for many processes applied in the food, beverage, dairy, biotech and pharmaceutical industries where they are used for product recovery for example of an active from fermentation broth, as well as product purification, fractionation and concentration.

Alfa Laval offers a comprehensive range of spiral membranes with different characteristics and properties.

Dairy series

For dairy applications Alfa Laval offers two series of tailor-made spiral membranes: The Dairy UF-PE series and the Dairy UF-pHt series. The spiral membranes of these series are USDA approved.

The dairy UF-PE spiral membrane, which is manufactured with polyester support material, is available with MWCO values between 5,000 and 20,000 dalton.

The dairy UF-pHt spiral membrane, which is cast on polypropylene backing paper, is available with MCWO values between 5,000 and 20,000 dalton.

ETNA series

The ETNA spiral membrane is made of composite fluoro polymer cast on polypropylene (PP) backing material. The ETNA spiral membrane is available in two different types with a molecular weight cut-off value (MWCO) of either 1,000 or 10,000 dalton.

FS series

The FS spiral membrane is also made of composite fluoro polymer cast on polypropylene backing material. The FS spiral membrane has a MWCO value of 100,000 dalton.

RC-PE Series

RC-PE series

The RC-PE spiral membrane is made of regenerated cellulose cast on polyester support material. The RC-PE spiral membrane has a MWCO value of 10,000 dalton.

RC-PP series

The RC-PP spiral membrane is made of regenerated cellulose cast on polypropylene support material. The RC-PP spiral membrane has a MWCO value of 10,000 dalton.

UF-PE series

The UF-PE spiral membrane is made of either polysulphone or polyethersulphone cast on polyester support material. The UF-PE spiral membrane is available in different types with MWCO values ranging from 5,000 to 25,000 dalton.

UF-pHt series

The UF-pHt spiral membrane is characterized by its tolerance towards high pH and temperature. It is made of polysulphone or polyethersulphone cast on polypropylene backing material. The UF-pHt spiral membrane is available in different types with MWCO values ranging from 2,000 to 100,000 dalton.

UFX-pHt series

The UFX-pHt spiral membrane is characterized by its ability to tolerate high pH and temperatures. The membrane, which is cast on polypropylene support material, is made of polysulphone, permanently hydrophilic. The UFX-pHt spiral membrane has a MWCO value of 10,000.

Benefits

- cost-effective operation due to low energy consumption

- long life time compared to traditional dead-end filtration

- cover a broad spectrum of flux properties and pore sizes

- available in different combinations of length, diameter and spacer size

- sanitary design with all materials in compliance with EU Regulation (EC) 1935/2004, EU Regulation 10/2011 and FDA regulations (CFR) Title 21

- same membrane types available as both flat sheet membranes and spiral membranes

- suitable for extensive range of processes

- manufactured by Alfa Laval's own membrane centre

Cómo funciona

La tecnología básica tras filtración por membrana implica el uso de una membrana semipermeable para separar un líquido en dos corrientes distintas.

El bombeo de este líquido a través de la superficie de la membrana crea una presión transmembrana positiva que permite el paso de cualquier componente más pequeño que la porosidad de la membrana, formando el permeado.

Cualquier componente más grande que el tamaño del poro no puede pasar y queda atrás en lo que llamamos retenido. La superficie de la membrana se mantiene libre de bloqueos por la fuerza del flujo de líquido que se mueve en paralelo a la superficie de la membrana.

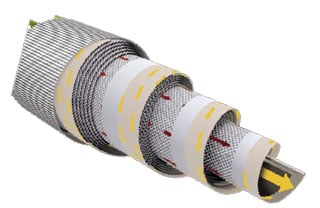

Una membrana en espiral se compone de una serie de «sobres» de membrana con 2 láminas de membrana separadas por una malla espaciadora de permeado, cada una pegada a un tubo central de recolección de permeado.

Entre cada par de envolturas hay un separador que crea el canal de alimentación, permitiendo que la alimentación fluya a lo largo de la membrana en espiral, mientras que el permeado que pasa a través de la membrana hacia la envoltura de la membrana fluye en un patrón en espiral hacia el tubo de recolección de permeado.

Rojo = Alimento/retenido.

Amarillo = Permeado.